|

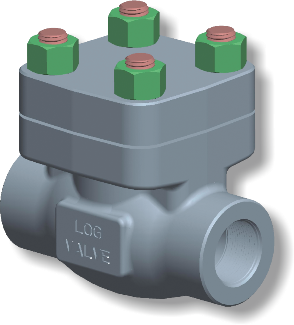

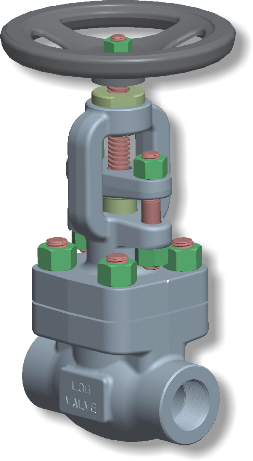

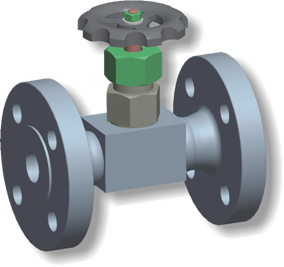

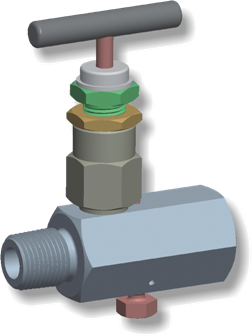

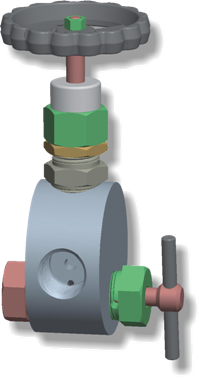

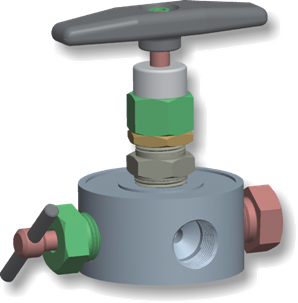

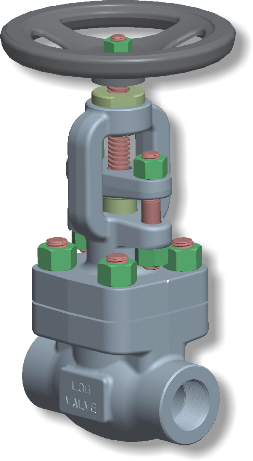

LE-LF type shut-off and control globe valve

This valve is designed according to API 602 Standard with forged body up to 50mm nominal size, for wide pressure-, and temperature ranges. The LE type valve is suitable for closing gas and liquid mediums streams while the LF type is suitable also for chocking. The valve seat and the disc is welded with Stellite 6 for the purpose of excellent abrasion resistance. The packing of the stuffing box is graphite (or Teflon) rings, which can be replaced during operation as well, in the uppermost position of the stem. The sealing of the bonnet is highly flexible spiral wound gasket. For higher pressures the sealing is a stainless steel gasket ring. The valves can be manufactured with threaded valve seats on demand.

Dimension range: DN 10 - 50 / NPS 3/8" - 2"

Pressure range: PN 16 – 400 / Class 150 - 2500

Temperature range: - 60°C - +550°C

Main features:

- Disc closing on conical surface

- Bolted bonnet

- Rising stem design with rising handwheel

- Ensured backseat

- Flanged, threaded, butt welded, or socket welded ends

Design options:

- Renewable valve seat

- Electric motor operation

- Pneumatic operation

Materials:

- ASTM A105

- ASTM A350 LF2

- ASTM A182 F11

- ASTM A182 F316(L)

Design standards:

- Construction: API 602 / ISO 15761

- Face to face length: ASME B16.10

- Socket welded type: ASME B16.11; DIN 3239

- Butt welded type: ASME B16.25; EN 12627

- Threaded type: ASME B1.20.1; ISO 228

- Flanged type: ASME B16.5; EN 1092-1; GOST 12815; GOST 12821

- Pressure test: API 602; EN 12266-1

- NACE design: NACE MR0175 / ISO 15156

|

|