Valves

|

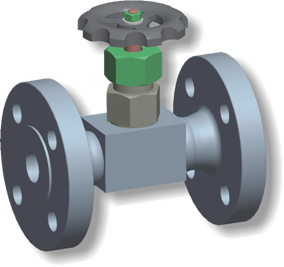

ASZ type needle valve This inside threaded needle valve is of simple design for wide pressure range. Long life is ensured by the non-rotating, self-centering valve tip and also by the weld on valve seat. The needle valve can be made with flanged, threaded, butt welded and socket welded ends as well. The needle valve can be built in the streamline of the pipeline in the direction of the arrow located on the valve body. Dimensions: DN 15; DN 25 / NPS 1/2”; 1” Main features:

Design options:

Materials:

Design standards:

|

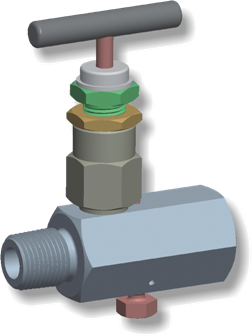

KFSZ type needle valve The KFSZ type needle valve stainless steel design made for up to 10000 psi (690 bar) nominal pressure. Long life is ensured by the non-rotating, self-centering tip and the male thread, which is out of contact with the medium located over the stuffing box and the plastic stem guard. Depending on the order the needle valve can be manufactured with connecting threads of NPT 1/2” outside or inside, and also M20x1,5 inside. The valve body can be blow off by the vent plug located on its bottom. The needle valve can be built in the streamline of the pipeline in the direction of the arrow located on the valve body. Dimension: 1/2” Main features:

Design options:

Material:

Design standards:

|

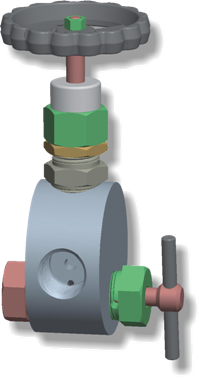

LM-1 type manometer needle valve The LM-1 type manometer needle valve makes possible the connection of the manometers to pipelines. The valve body is a four way cock, and can be manufactured with NPT 1/2” or M20x1,5 connecting threads depending to the order. The valve body can be blown off to provide easy installation or dismantling under pressure as well. The manometer needle valve can be built in the streamline of the pipeline in the direction of the arrow located on the valve body. Dimension: DN 15 Main features:

Design options:

Materials:

Design standards:

|

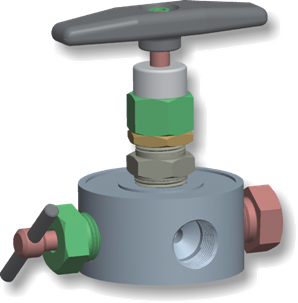

LM-2 type manometer needle valve The LM-2 type manometer needle valve differs from the LM-1 type one only in the arrangement of the valve body connections. Dimension: DN 15 Main features:

Design options:

Materials:

Design standards:

|

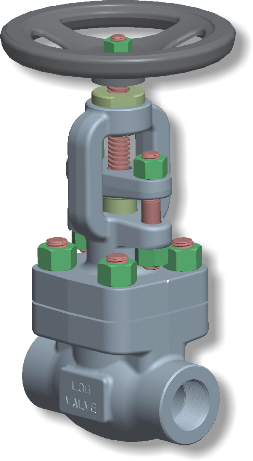

LE-LF type shut-off and control globe valve This valve is designed according to API 602 Standard with forged body up to 50mm nominal size, for wide pressure-, and temperature ranges. The LE type valve is suitable for closing gas and liquid mediums streams while the LF type is suitable also for chocking. The valve seat and the disc is welded with Stellite 6 for the purpose of excellent abrasion resistance. The packing of the stuffing box is graphite (or Teflon) rings, which can be replaced during operation as well, in the uppermost position of the stem. The sealing of the bonnet is highly flexible spiral wound gasket. For higher pressures the sealing is a stainless steel gasket ring. The valves can be manufactured with threaded valve seats on demand. Dimension range: DN 10 - 50 / NPS 3/8" - 2" Main features:

Design options:

Materials:

Design standards:

|

|

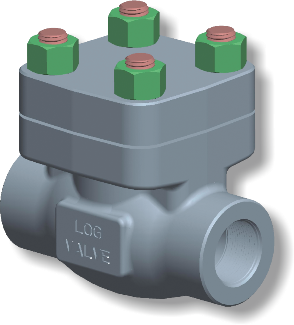

LVCS-1 type spring return check valve A forged body check valve manufactured according to API 602 Standard with up to 50 mm nominal size, for wide pressure-, and temperature ranges. The piston type check valve is made with helical spring returning closing element. The valve can be installed only for one way streams. In case of back stream the valve closes due to spring force and the pressure of medium. The valve seat and the disc is welded with Stellite 6 for the purpose of excellent wearing resistance. The sealing of the bonnet is highly flexible spiral wound gasket. At higher pressures the sealing is made of stainless steel gasket ring. The check valves can be manufactured also with threaded valve seats on demand. Dimension range: DN 10 - 50 / NPS 3/8" - 2" Main features:

Design options:

Materials:

Design standards:

|

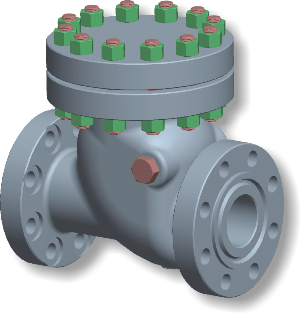

LVCS-2 type swing check valve This swing type check valve is made for wide pressure-, and temperature ranges. The valve can be installed only for one way streams. In case of back stream the valve closes due to own weight of the closing element and also the pressure of the medium. The valve body in welded for smaller sizes and of casted design for bigger sizes. The valve seat and the disc is welded with Stellite 6 for the purpose of excellent wearing resistance. The valve seat can be made in welded or renewable, threaded versions. The sealing of the bonnet is highly flexible spiral wound gasket. For higher pressures the sealing is made of stainless steel gasket ring, or self-sealing graphite ring. Dimension range: DN 50 - 150 / NPS 2" - 6" Main features:

Design options:

Materials:

Design standards:

|